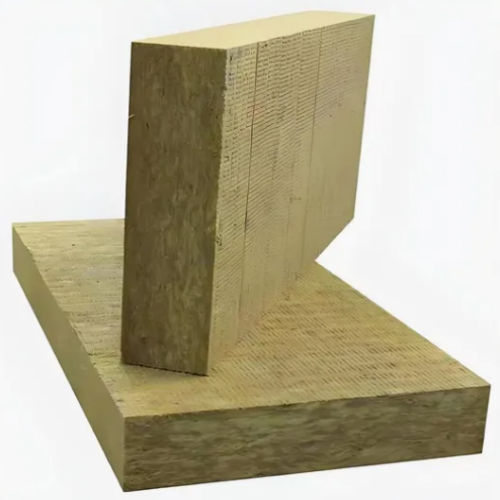

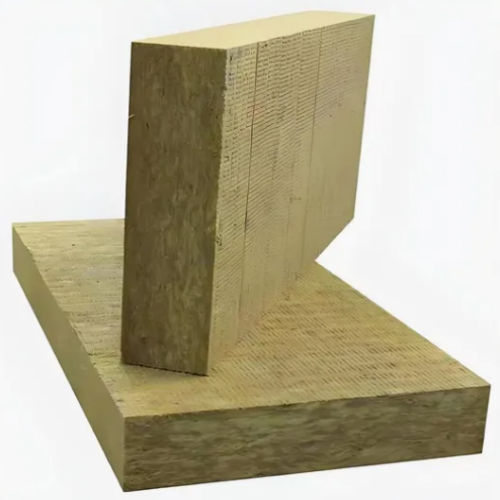

rock wool board

Rock wool is made from high-quality natural rocks such as basalt and dolomite as the main raw materials. After melting, it is spun into fibers by a four roll centrifuge at high speed and then sprayed with a small amount of binder. After solidification, it is processed into products of different spec

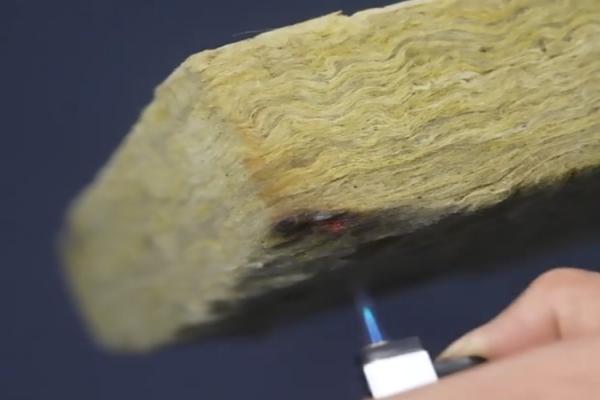

Rock wool is made from high-quality natural rocks such as basalt and dolomite as the main raw materials. After melting, it is spun into fibers by a four roll centrifuge at high speed and then sprayed with a small amount of binder. After solidification, it is processed into products of different specifications and uses. Its characteristics include insulation, heat insulation, fire prevention, sound absorption, noise reduction, non corrosiveness, environmental friendliness, hydrophobicity, especially non flammability and high melting point. Its fiber opening structure makes it widely used in the fields of fire prevention, sound absorption and noise reduction. In the industrial field, it is widely used in power, petrochemical, and other industrial sectors. The product is suitable for process temperature control, energy conservation, and personal protection of equipment and pipelines such as boilers, steam pipes, heat exchangers, reactors, ovens, kilns, etc. In the field of architecture, it is widely used for fire prevention, thermal insulation, energy conservation, sound absorption and noise reduction, and anti condensation and condensation of building structures such as roofs, exterior walls, ceilings, and sandwich floors in commercial buildings, residential buildings, factories, and public places.

Other specifications displayed

Specification: 1200 * 600 * (25-150) mm (size can be customized)

Density: 60, 80, 100, 120, 160kg/m3